A unique international hub dedicated to Eco-Innovation

E2P2L

A unique international hub dedicated to Eco-Innovation

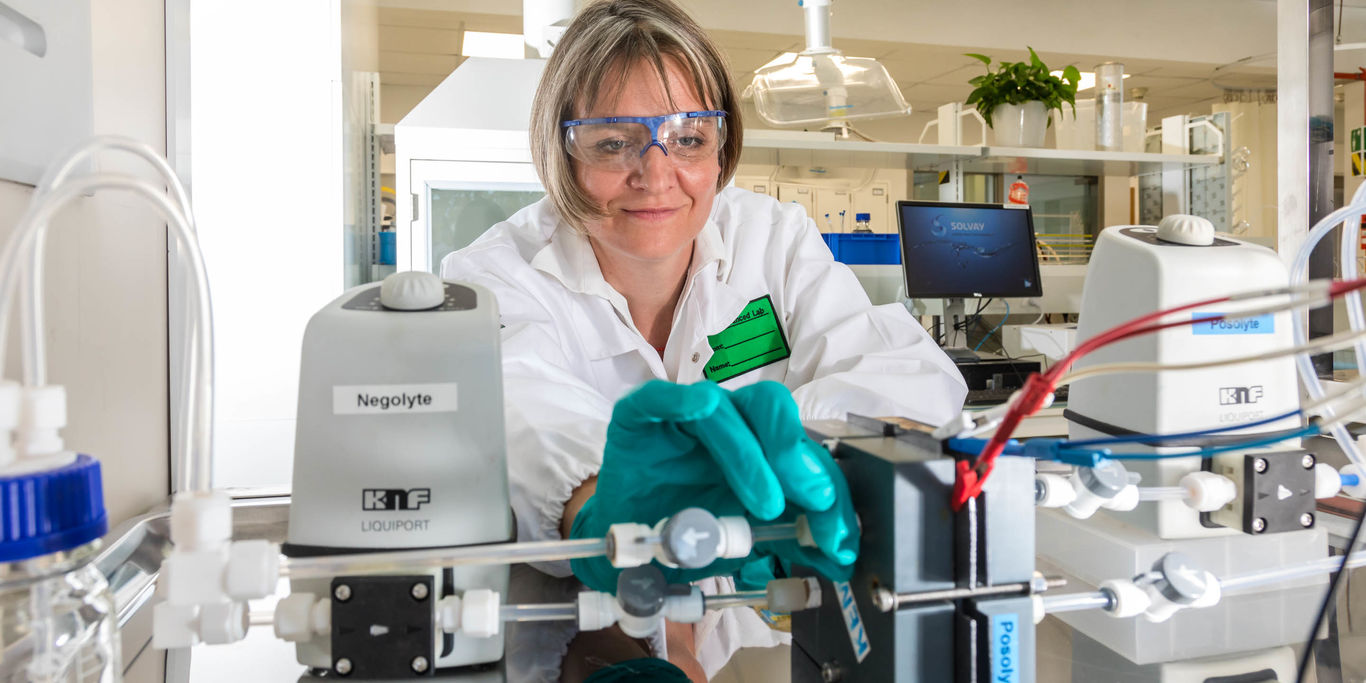

Eco-Innovation is key to deliver both environmental benefit and ensure that the cost of new technologies are acceptable by the markets. By combining scientific and industrial excellence, E2P2 is a unique international team dedicated to Eco-Innovation, capable of inventing and developing breakthrough technologies for sustainable chemistry.