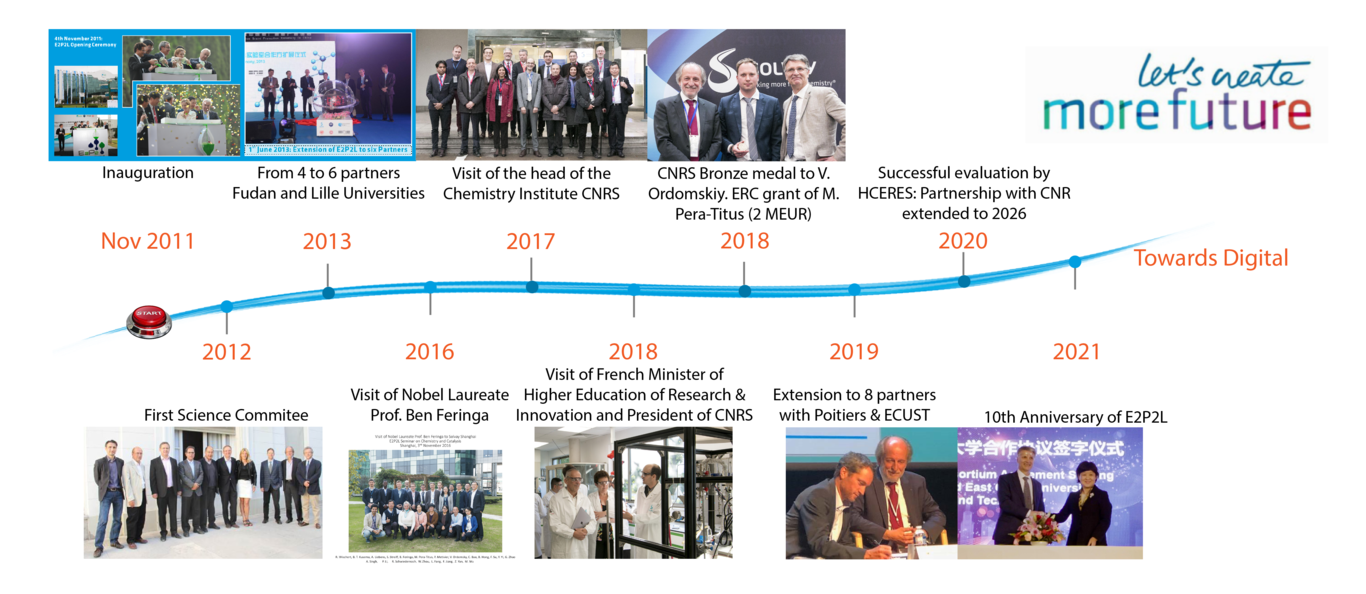

History

The story of Syensqo's Eco-Efficient Products and Processes Laboratory (E2P2L) started in August 2010 when the four funding partners CNRS, ENSL, ECNU, and Syensqo (Rhodia legacy at the time), signed a letter of intent stating their willingness to conduct research together at the Shanghai Expo site.

The founding partners decided to create an international laboratory in China dedicated to sustainable chemistry merging industrial and academic research.

Structure

Chronologically, the E2P2 laboratory was set up in four consecutive steps:

- Step 1: an official CNRS international joint lab (UMI 3464) was created in March 2011 between the French National Center for Scientific Research (CNRS) and Rhodia (now Syensqo). A contract defined five main projects and partner commitments (e.g. number of sponsored researchers and investments).

- Step 2: A consortium agreement was signed between CNRS, Rhodia, the Ecole Normale Supérieure de Lyon (ENS Lyon), and the East China Normal University (ECNU) with strong support from the Rhône-Alpes region.

- Step 3: In 2013, the University of Lille Sciences et Technologies (LST) and the University of Fudan (Shanghai) joined the E2P2L consortium, leading to the present six-partner architecture. CNRS and Syensqo perform as the administrative supervisors of the unit, whereas the Unité de Catalyse et Chimie du Solide (UCCS), being federated to LST, was selected as the E2P2L mirror laboratory by CNRS in France.

- Step 4: In 2019, we welcomed two new partners to E2P2L: University of Poitiers (IC2MP, France) and East China University of Science and Technology (ECUST, China) to strengthen our competencies in biobased chemistry and CO2 utilization (IC2MP), and modeling (ECUST). In addition to the 8 official partners, strong collaborations were established with ShanghaiTech and the Lanzhou Institute of Chemical Phys-ics (LICP/CAS).

- Apart from the 8 official partners, strong collaborations were established with French and Chinese universities and research institutions, among which the East China University of Science and Technology (ECUST), the University of Poitiers (IC2MP), and the Lanzhou Institute of Chemical Physics (LICP/CAS). In 2016, IC2MP was selected by CNRS as the second E2P2L mirror laboratory in France.

E2P2L remains a unique laboratory: it operates at the interface between academic and industrial research with a sound differentiation from other joint research units, both in China and abroad. E2P2L can capture local opportunities such as leveraging local scientific developments in academia, accessing local scientist talent pool, addressing local environmental issues, and supporting regional growth in Asia.

The lab has been structured by creating an international joint lab UMI 3464 (UMI – Unite Mixte Internationale in French) between Syensqo and CNRS. Such set-up allows having two partners providing a minimum of funds and resources to the team. Then, a consortium agreement has been signed by all six members of E2P2L stating that the members will collaborate on research projects within the new lab.

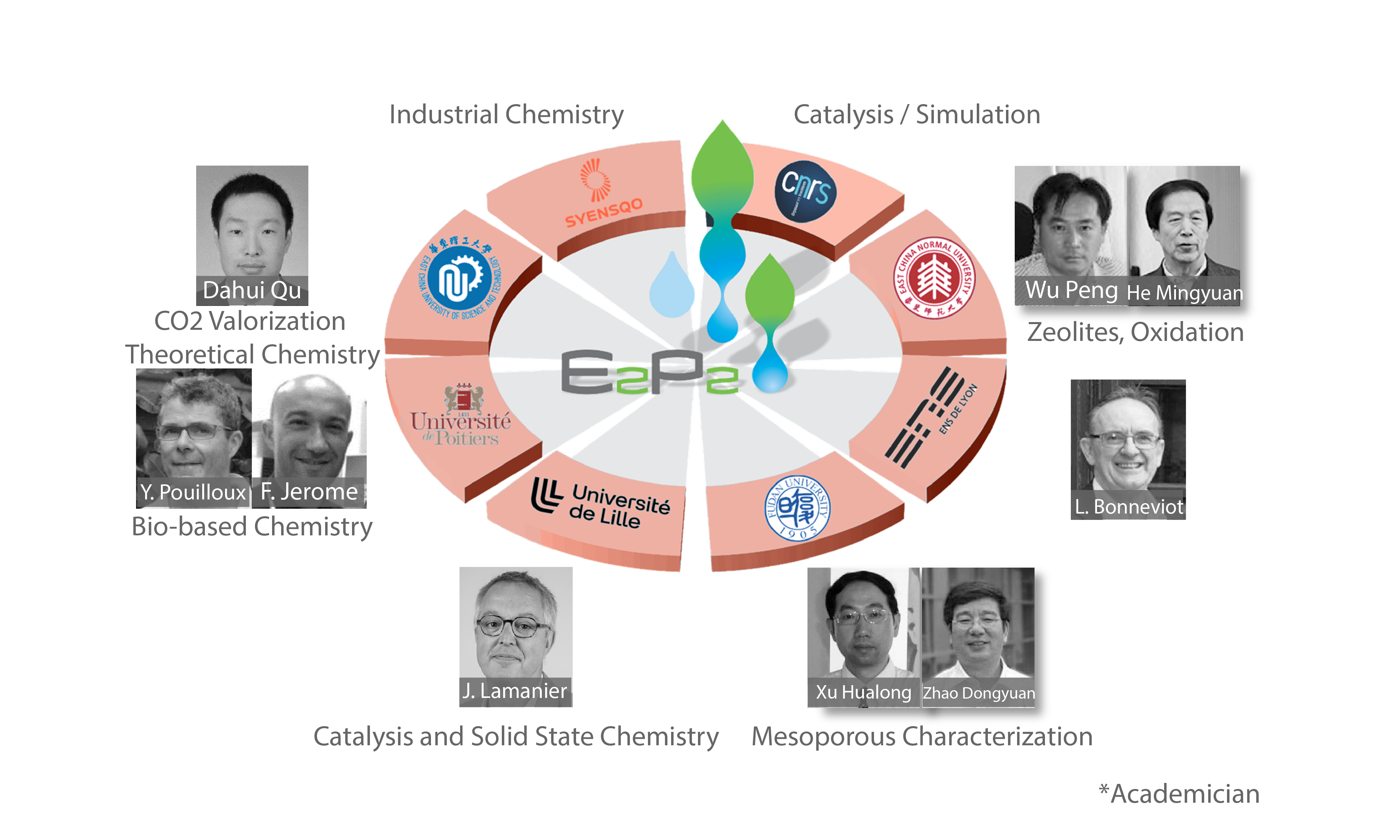

All eight partners of E2P2L are recognized in their respective fields at an international level. Each partner brings unique and complementary competences and capabilities to the consortium:

- CNRS — Heterogeneous catalysis, electrochemistry, strong international research network,

- ENSL — Hybrid materials and theoretical chemistry applied to catalysis,

- ECNU — Zeolite synthesis and application to catalysis,

- UCCS — High-throughput platform for catalyst synthesis, characterization and testing,

- Fudan — Mesoporous materials and advanced characterization techniques,

- ECUST — CO2 valorization and theoretical chemistry,

- IC2MP – Chemistry with bio-based reagents,

- Syensqo — Industrial chemistry, economic evaluation, and life-cycle assessment.

This partnership has demonstrated both tangible and intangible benefits. Beyond the financial, intellectual and logistic contribution of the partners and the international visibility, the consortium offers access to a strong academic network, including academicians and Noble Prize laureates. Besides, the unit benefits from a privileged access to a wide range of modern equipment and advanced technologies. The academic affiliation of E2P2L provides access to public funding from France, Europe and China.

Research Strategy

The research strategy, both academic and applied, focuses on advanced chemo-catalysis applied to the production and application of specialty chemicals, while not excluding breakthrough solutions for the synthesis of commodities. Examples of specialty chemicals encompass bio-based surfactants, bio-based monomers, polymers building blocks, green solvents or additives. The use of sustainable feedstocks such as biomass or carbon dioxide is favored.